Types of Fertilizer Production Line and How Much They Cost

Investing in a fertilizer production line is a significant step toward building a profitable and sustainable agribusiness. Understanding the different types of fertilizer equipment and their associated costs is crucial for making an informed decision. This comprehensive guide from Yuhheng Technology Co., Ltd. will help you navigate your options and budget effectively.

Understanding the Two Main Types of Fertilizer Production Lines

The choice of a production line primarily depends on your desired final product. The two most common types are powder fertilizer lines and granular fertilizer lines.

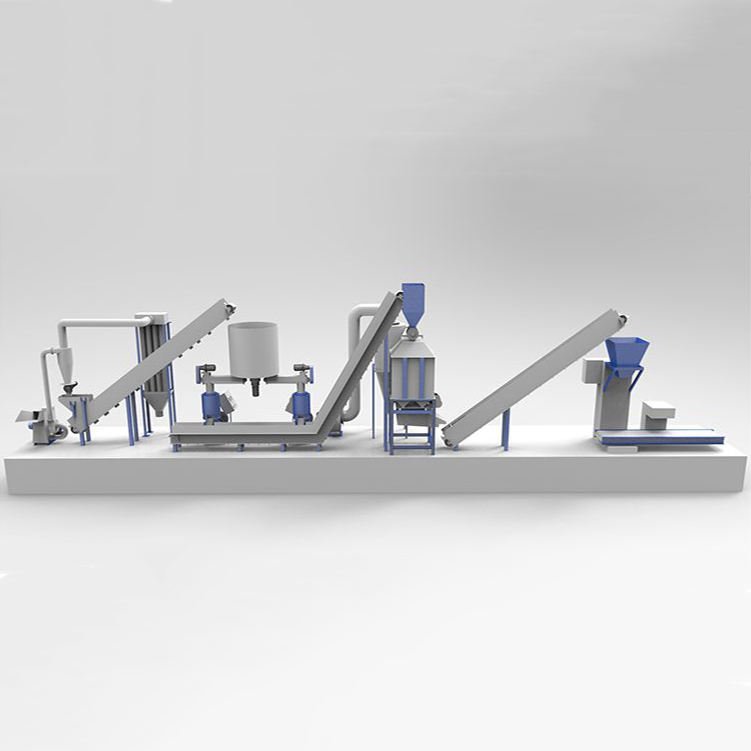

1. Powdered Fertilizer Production Line

This system is designed to produce fine, uniform powdered organic fertilizer. It is generally simpler, requires less equipment, and has a lower initial investment.

Key Processes and Equipment:

- Fermentation: A compost turner (windrow turner) is used to aerate and mix the raw materials (like livestock manure), accelerating the decomposition process.

- Crushing: A semi-wet material crusher pulverizes the fermented compost into a fine powder.

- Screening: A drum screening machine separates oversized particles for re-crushing, ensuring a consistent product size.

- Packaging: An automatic packaging scale bags the final powdered fertilizer for sale.

Ideal For: Small to medium-scale operations, organic farms, and those starting in the fertilizer manufacturing business with a limited budget.

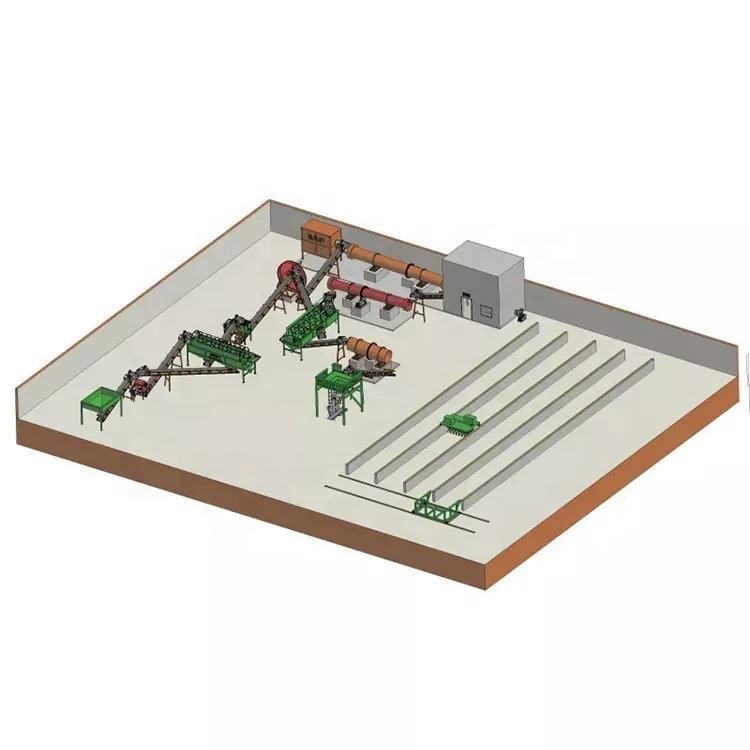

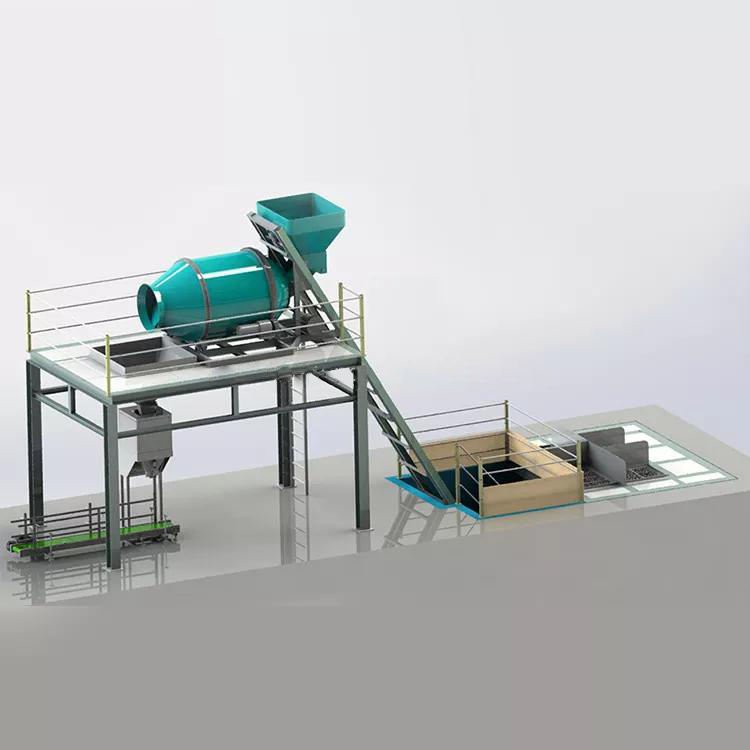

2. Granular Fertilizer Production Line

This is a more advanced system that transforms powdered material into dense, uniform granules. Granules are preferred for their ease of application, reduced dust, and improved nutrient release control. This line includes all the equipment from the powder line, plus several additional key machines.

Additional Key Equipment:

- Mixing: A horizontal mixer ensures an even blend of all powdered ingredients and additives.

- Granulating: The heart of the line. A granulator (e.g., rotary drum granulator, flat die pellet mill, or new organic fertilizer granulator) forms the powder into granules.

- Drying & Cooling: A rotary dryer reduces the moisture content of the granules, while a rotary cooler brings them down to room temperature, hardening them for storage.

- Coating: A coating machine applies a protective powder to prevent moisture absorption and caking.

- Final Packaging: An automatic packaging scale packages the finished granules.

Ideal For: Large-scale commercial operations aiming to produce high-value, market-ready granular fertilizer for a wider distribution.

How Much Does a Fertilizer Production Line Cost?

The fertilizer plant cost is not a fixed number; it varies significantly based on several factors. Providing an exact price without a project review is impossible, but we can outline the key price ranges and influencing factors.

Key Factors Influencing Cost:

- Scale & Capacity: A small-scale line producing 1-3 tons per hour will cost far less than a large plant producing 10-30 tons per hour.

- Automation Level: Fully automatic lines with PLC control systems are more expensive than semi-automatic or manual lines.

- Equipment Material: Standard carbon steel is more affordable, but stainless steel contact parts are recommended for durability and corrosion resistance, adding to the cost.

- Configuration: The specific models and number of machines you choose (e.g., the type of granulator) will impact the final price.

Estimated Price Ranges

- Small Powder Fertilizer Production Line: For a basic, semi-automatic line with a capacity of 1-2 tons per hour, the investment can start from $25,000 – $50,000.

- Complete Granular Fertilizer Production Line: For a standard, automatic line with a capacity of 3-5 tons per hour, including granulation, drying, and cooling, prices typically range from $70,000 – $150,000.

- Large-Scale Granular Plant: For a high-capacity (10+ TPH), fully automated production plant with advanced dust control and packaging systems, the investment can range from $200,000 to $500,000+.

Remember: These are broad estimates. The best way to get an accurate fertilizer equipment price is to consult directly with a manufacturer.

Get Your Customized Solution and Quote from Yuhheng Tech

At Yuhheng Technology Co., Ltd., we don’t just sell machines; we provide complete, customized solutions. We understand that every project is unique.

Our experts will work with you to:

- Analyze your raw materials and desired output.

- Recommend the most efficient and cost-effective type of fertilizer production line.

- Provide a detailed layout and a transparent, all-inclusive quotation.

Don’t let uncertainty delay your project. Contact Yuhheng Tech today for a free consultation and a customized quote tailored to your specific production needs and budget. Let’s build your path to success together.