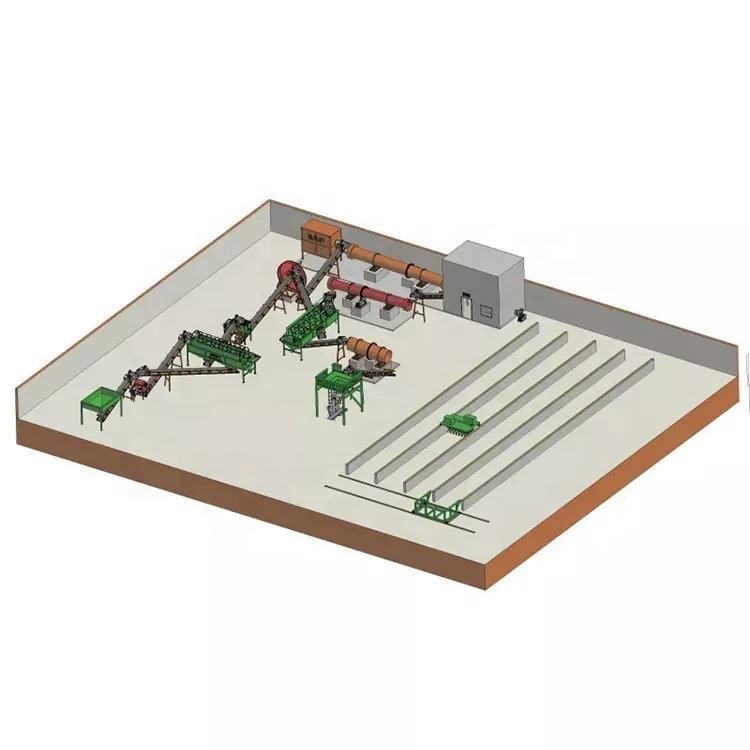

Animal Feed Pellet Production Line Price & Daily Maintenance Guide

Entering the animal feed production industry requires a solid understanding of equipment investment and operational costs. For entrepreneurs and agricultural businesses considering this venture, the price of the production line and its daily maintenance are two fundamental concerns. This guide from Yuhheng Technology Co., Ltd. provides a clear breakdown to help you evaluate your investment.

How Much Does an Animal Feed Pellet Production Line Cost?

The cost of an animal feed pellet production line varies significantly based on capacity, automation level, and the specific formula you plan to produce (e.g., poultry, livestock, or aquatic feed). Higher capacity and automation lead to a greater initial investment but also higher long-term efficiency.

Here is a general overview of the price ranges:

Key Price Ranges:

- Small-Scale / Starter Line: A semi-automatic line with a capacity of 1-2 tons per hour, suitable for small farms or local cooperatives. This typically includes a grinder, mixer, pellet mill, and cooler. The investment can start from $20,000 to $50,000.

- Medium-Scale Commercial Line: A popular choice for dedicated feed mills. This automatic line with a capacity of 3-5 tons per hour includes hammer mills, screw conveyors, conditioning bins, pellet mills, coolers, crumblers, and automatic packaging machines. Prices for this complete setup typically range from $60,000 to $150,000.

- Large-Scale Industrial Plant: For high-volume production (10+ tons per hour) with full PLC automation, precision batching systems, fat coating systems, and advanced packaging lines, the investment can range from $200,000 to $500,000 or more.

Factors That Influence the Total Cost:

- Raw Material Formulation: Harder materials like corn or soy require more powerful (and expensive) crushers and pellet mills.

- Pellet Mill Die Size and Power: The capacity and motor power of the pellet machine itself are major cost drivers.

- Automation Level: PLC control systems for automatic batching and sequencing add cost but improve consistency and reduce labor.

- Auxiliary Equipment: The need for additional equipment like counterflow coolers, fat sprayers, or crumblers will affect the final price.

Is Daily Maintenance Complicated?

The daily maintenance of an animal feed pellet line is systematic and manageable. It is not considered overly complicated but requires consistency and attention to detail to ensure smooth operation, prevent breakdowns, and maintain pellet quality.

Essential Daily Maintenance Tasks:

- Thorough Cleaning: This is the most critical daily task. Residual feed powder in the mixer, conveyors, coolers, and especially the pellet mill die and rollers can harden, attract pests, and cause cross-contamination between batches. A complete clean-out after each production run is essential.

- Lubrication: All bearings on motors, conveyors, the pellet mill, and other moving parts require regular greasing according to the manufacturer’s schedule to prevent wear and ensure smooth operation.

- Inspection and Adjustment:

- Pellet Mill Die and Rollers: Check for wear and proper tension. This is the heart of the operation and must be in optimal condition to produce quality pellets.

- Hammer Mill Screens and Hammers: Inspect for wear and tear to maintain proper grinding efficiency.

- Belts and Transmissions: Check for proper tension and signs of wear.

- Conditioning Check: Ensure the steam conditioning system is functioning correctly to provide the right temperature and moisture for effective pelleting.

What Makes Maintenance Manageable?

- Predictable Schedule: Maintenance follows a clear, repeatable routine. Once established, it becomes a standard part of the workflow.

- Robust Design: High-quality lines from Yuhheng Tech are built for industrial durability and designed with accessibility in mind, making daily checks and cleaning easier.

- Focused on Prevention: The daily tasks are preventative, designed to catch small issues before they lead to costly downtime or poor product quality.

In summary, while daily upkeep is required, it is a straightforward process of cleaning, lubricating, and inspecting. The effort is a necessary and valuable practice to protect your investment and ensure consistent, high-quality feed production.

Get Your Customized Feed Pellet Solution from Yuhheng Tech

Choosing the right production line is key to your profitability. At Yuhheng Technology Co., Ltd., we specialize in designing complete feed pellet production solutions tailored to your specific raw materials, target animals, and production goals.

We provide:

- Expert Consultation: We help you select the right capacity and configuration to maximize your ROI.

- Transparent Quotation: A detailed price breakdown based on your needs, with no hidden costs.

- Comprehensive Training & Support: We ensure your team is fully trained on operation and maintenance procedures, and we provide reliable after-sales support.

Contact Yuhheng Tech today for a free consultation and a detailed quotation. Let us help you build a efficient and profitable animal feed production business with the right equipment and expert support.