BB Fertilizer Production Line Price & Key Installation Considerations

BB Fertilizer Production Line Cost Analysis

The investment for a BB fertilizer production line varies based on capacity, automation level, and equipment configuration. Here’s a detailed cost breakdown:

Equipment Investment Range:

- Basic Semi-Automatic Line (1-2 tons/hour): $15,000 – $35,000

- Standard Automatic Line (3-5 tons/hour): $40,000 – $80,000

- Large-Scale Plant (8-15+ tons/hour): $90,000 – $200,000+

Cost Determinants:

- Automation level (manual vs PLC control)

- Mixer type and capacity

- Material handling system complexity

- Packaging system sophistication

- Equipment material quality

Critical Installation Considerations

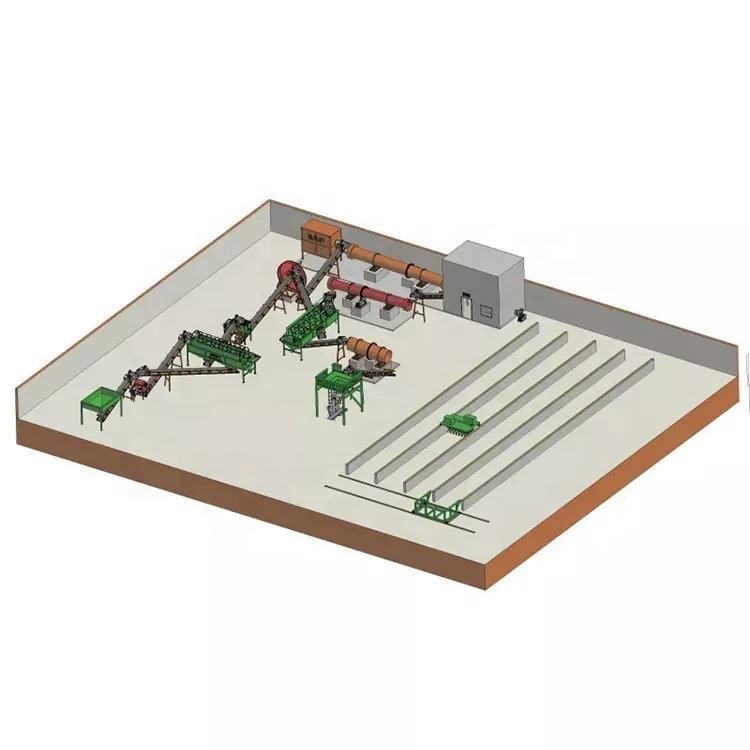

1. Site Preparation & Foundation Requirements

- Ensure adequate space allocation for equipment layout and material flow

- Prepare reinforced concrete foundations with proper load-bearing capacity

- Maintain level installation surfaces with precision tolerance (±3mm)

- Allow sufficient clearance for maintenance access and operation

2. Utility Connection Points

- Electrical system: 380V/50Hz three-phase power with proper grounding

- Compressed air requirements: 0.6-0.8MPa pressure, 0.5-1.0m³/min capacity

- Lighting system: Adequate illumination (200-300 lux) in working areas

- Ventilation: Proper air circulation to prevent dust accumulation

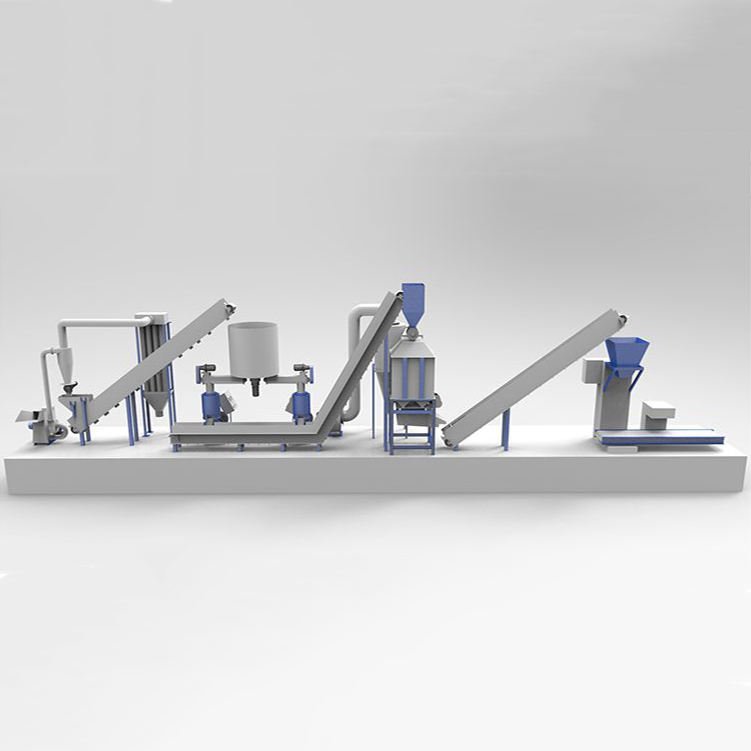

3. Equipment Installation Sequence

- Begin with primary structural framework assembly

- Install material storage and handling systems (silos, conveyors)

- Position and level mixing equipment with laser alignment

- Integrate control systems and electrical connections

- Commission packaging and bagging systems last

4. Key Technical Installation Requirements

- Mixer Installation: Ensure perfect leveling to prevent uneven wear

- Conveyor Systems: Maintain precise alignment and proper tensioning

- Electrical Systems: Implement proper cable management and safety disconnects

- Control Systems: Secure stable mounting with adequate ventilation

5. Safety & Compliance Installation

- Install emergency stop systems at strategic locations

- Implement proper machine guarding as per safety standards

- Ensure adequate dust collection system installation

- Verify all electrical installations meet local regulations

6. Post-Installation Verification

- Conduct comprehensive system alignment checks

- Verify all safety interlocks and emergency stops

- Test material flow through complete production line

- Calibrate weighing and batching systems for accuracy

Professional Installation Support from Yuhheng Technology

At Yuhheng Technology Co., Ltd., we provide comprehensive installation services that ensure optimal performance and longevity of your BB fertilizer production line.

Our Installation Services Include:

- Pre-installation site assessment and planning

- Professional equipment installation by certified technicians

- System integration and calibration services

- Operator training and technical documentation

- Post-installation maintenance support

Important Installation Recommendations:

- Always use factory-trained installation technicians

- Follow manufacturer’s installation specifications precisely

- Conduct thorough testing before full-scale operation

- Maintain detailed installation records for future reference

- Schedule regular maintenance from installation completion

Proper installation is fundamental to achieving optimal equipment performance, ensuring operational safety, and maximizing equipment service life. Cutting corners during installation often leads to increased downtime and higher maintenance costs.

Conclusion

Investing in a BB fertilizer production line requires careful consideration of both costs and installation requirements. By understanding these key factors and partnering with an experienced equipment provider like Yuhheng Technology, you can ensure a successful project implementation that delivers long-term operational efficiency and profitability.

Contact Yuhheng Technology today for a detailed project assessment and professional installation consultation. Our experts will help you navigate every step of your BB fertilizer production line implementation, from initial planning to final commissioning.