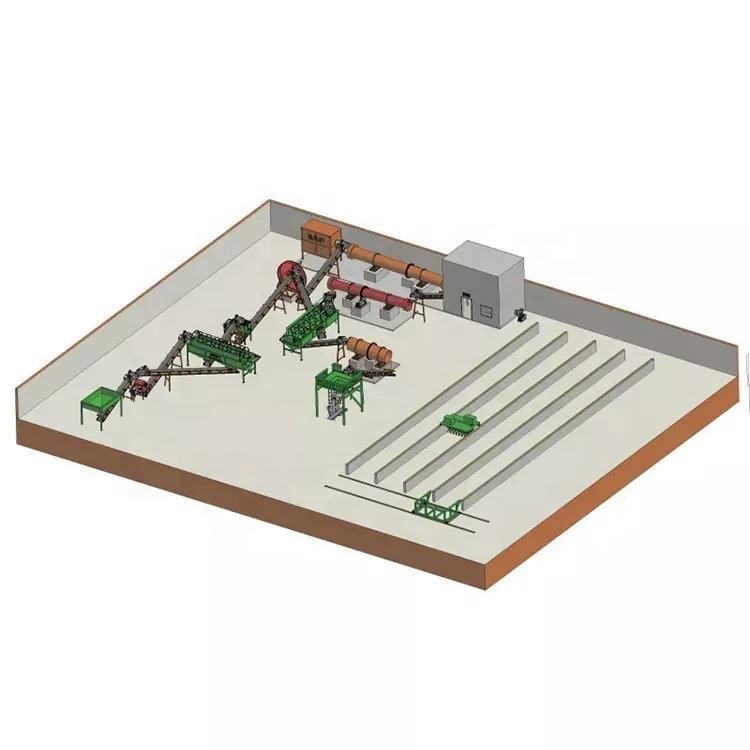

For agricultural businesses looking to enter the blended fertilizer market, understanding the investment and operational requirements of a BB fertilizer production line is crucial. This guide from Yuhheng Technology Co., Ltd. will address two of the most common questions we receive: “How much does it cost?” and “Is daily maintenance complicated?”

How Much Does a BB Fertilizer Production Line Cost?

The price of a BB fertilizer (bulk blend fertilizer) production line is not a one-size-fits-all figure. It varies significantly based on the level of automation and capacity you require. Generally, these systems are more affordable than granulation lines but come in different configurations.

Key Price Ranges:

- Small Semi-Automatic Line: A basic line with manual weighing and a simple mixer, suitable for small-scale or starter operations (1-3 tons per hour), can have an initial investment starting from $15,000 to $35,000.

- Standard Automatic Line: This is the most common choice. It includes automatic batching scales, a conveyor system, a high-quality mixer, and an automatic packaging scale. For a capacity of 3-8 tons per hour, prices typically range from $40,000 to $80,000.

- Large Fully-Automatic Plant: For high-volume production (8-15+ tons per hour) with a fully integrated PLC control system for precise recipe management, the investment can range from $90,000 to $200,000+.

What Influences the Price?

- Automation Level: PLC-controlled systems are more expensive than semi-automatic ones.

- Equipment Quality: The choice of mixer type (e.g., horizontal mixer vs. dual-shaft paddle mixer) and the material of construction (e.g., carbon steel vs. stainless steel contact parts) affect durability and cost.

- Capacity: Higher throughput requires larger, more powerful equipment.

- Additional Features: Options like automated bag placers and palletizers will add to the total cost.

Is Daily Maintenance of a BB Fertilizer Line Trouble-Free?

A significant advantage of a BB fertilizer production line is its relative simplicity, which translates to straightforward and manageable daily maintenance. It is generally not considered troublesome if a basic routine is followed.

Essential Daily Maintenance Tasks:

- Thorough Cleaning: This is the most critical task. After each production run or at the end of the day, the entire system—especially the mixer, hoppers, and conveyors—must be cleaned out completely. This prevents cross-contamination between different fertilizer blends and avoids material caking and corrosion.

- Lubrication: Moving parts, such as bearings on conveyors and mixers, need regular lubrication as specified in the equipment manual to ensure smooth operation and prevent premature wear.

- Inspection: A quick visual inspection for signs of wear on belts, chains, and screws should be part of the daily routine. Checking for loose bolts or unusual noises can help catch small problems before they lead to major downtime.

What Makes Maintenance Easier?

- Simple Mechanics: Unlike complex granulation lines with dryers and coolers, BB lines have fewer moving parts. The core process is batching and mixing.

- No Water or Heat Involved: Since there is no granulation or drying process, you avoid the maintenance issues associated with moisture, heat, and corrosion that are common in other production lines.

- Modular Design: High-quality lines from Yuhheng Tech are designed for easy access to key components, making cleaning and inspection faster and more efficient.

In summary, while daily cleaning is non-negotiable, the maintenance of a BB fertilizer line is largely preventative and straightforward. There are no complex processes that require constant technical adjustment, making it an operation that can be managed reliably with standard training.

Your Partner for a Hassle-Free Investment

At Yuhheng Technology Co., Ltd., we provide more than just equipment. We provide a complete solution tailored to your budget and production goals. Our BB fertilizer production lines are engineered for reliability and easy maintenance to maximize your uptime and profitability.

We offer:

- Transparent Pricing: Customized quotes with no hidden costs.

- Training & Support: Comprehensive guidance on operation and maintenance.

- Quality Equipment: Durable machinery built to last, reducing long-term repair needs.

Contact Yuhheng Tech today for a free consultation and quotation. Let our experts help you design the most efficient and cost-effective BB fertilizer production line for your business needs.

Leave a Comment

Your email address will not be published. Required fields are marked *