Transforming chicken manure into valuable organic fertilizer is a smart business decision for poultry farms and agricultural entrepreneurs. Two of the most pressing questions for anyone considering this venture are about the initial investment and the ongoing operational effort. This guide from Yuhheng Technology Co., Ltd. will provide clear, practical answers to both.

How Much Does a Chicken Manure Fertilizer Production Line Cost?

The cost of a production line specifically designed for chicken manure is highly variable. It depends primarily on the scale of your operation and whether you aim to produce powdered or granular fertilizer. Granulation lines are more complex and therefore more expensive.

Here is a general overview of the investment required:

Key Price Ranges:

- Small-Scale Powder Line: A basic, semi-automatic line focused on producing powdered fertilizer, ideal for a single farm or a small startup. With a capacity of 1-2 tons per hour, the investment can start from $30,000 to $60,000.

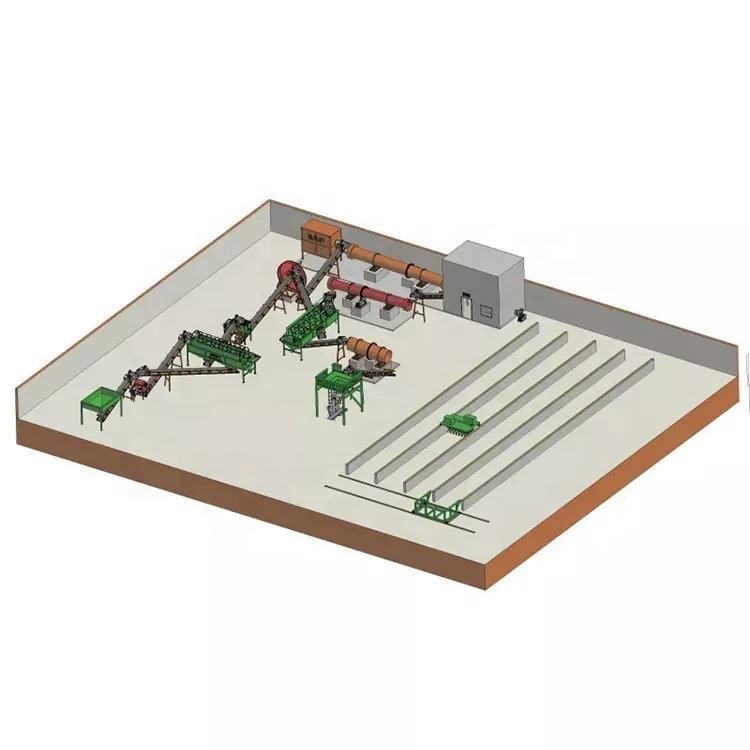

- Standard Granular Line: This is the most common commercial choice. A complete automatic line that includes fermentation, crushing, granulation, drying, cooling, and packaging. For a capacity of 3-5 tons per hour, prices typically range from $80,000 to $170,000.

- Large-Scale Granular Plant: For high-volume, industrial-level production (10+ tons per hour) with full PLC automation, advanced odor control systems, and automated packaging lines, the investment can range from $250,000 to $600,000 or more.

Crucial Factors Influencing Your Specific Cost:

- Pre-treatment & Fermentation: Chicken manure has high moisture and ammonia content. The required pre-treatment system (e.g., dewatering, mixing with bulking agents) and the size of the fermentation area (e.g., compost turners, fermenter tanks) significantly impact the total cost.

- Corrosion Resistance: Chicken manure is corrosive. Equipment with stainless steel contact parts, while more expensive upfront, is a wiser long-term investment for durability.

- Odor Control Systems: Investing in biofilters or other odor mitigation technologies adds to the cost but is often essential for environmentally compliant and community-friendly operation.

Is Daily Maintenance Complicated?

A chicken manure fertilizer production line requires consistent daily care, but it is not overly complex. The maintenance is largely preventative and revolves around hygiene and basic mechanical checks. The corrosive nature of the raw material makes diligent cleaning the top priority.

Essential Daily Maintenance Tasks:

- Thorough Cleaning: This is the most critical task. Residual chicken manure will harden and accelerate corrosion on equipment surfaces. The mixer, granulator, conveyor belts, and especially the screen mesh must be cleaned out after each shift to prevent clogging and cross-contamination.

- Lubrication: All moving parts with bearings (conveyors, crusher, granulator, dryer) need regular lubrication as per the manual to ensure smooth operation and protect against wear. Use grease that can resist washout.

- Visual Inspection: A daily walk-around is essential. Check for wear on vulnerable parts like crusher hammers, granulator dies, and screen meshes. Look for loose bolts, unusual vibrations, or noises that might indicate a problem needing early attention.

What Makes Maintenance Manageable?

- Predictable Routine: The tasks are repetitive and quickly become part of a standard operating procedure. It’s about diligence, not technical complexity.

- Robust Equipment Design: At Yuhheng Tech, we build our lines with easy access panels and designs that simplify cleaning and inspection, specifically considering the challenges of processing manure.

- Professional Support: We provide comprehensive training for your team on these specific maintenance routines and offer readily available spare parts and remote support to minimize any potential downtime.

In summary, daily maintenance is a mandatory but straightforward process. The effort is a small price to pay for turning a waste product into a profitable, sustainable commodity.

Get Your Customized Chicken Manure Solution from Yuhheng Tech

Chicken manure has specific processing requirements. At Yuhheng Technology Co., Ltd., we specialize in designing tailored solutions that efficiently handle high moisture and corrosiveness, ensuring a high-quality final product and a strong return on investment.

We provide:

- Expert Design: We engineer lines specifically for chicken manure, ensuring efficient dewatering, fermentation, and granulation.

- Transparent Pricing: A detailed quotation based on your raw material analysis and production goals, with no hidden costs.

- Lifetime Support: From installation and training to supply of spare parts, we are your long-term partner for success.

Contact Yuhheng Tech today for a free consultation and a custom quote. Let our experts help you build a profitable and environmentally sound fertilizer business from your chicken manure resources.

Leave a Comment

Your email address will not be published. Required fields are marked *