Investing in a BB fertilizer (bulk blend fertilizer) production line offers an efficient way to enter the blended fertilizer market. For business owners evaluating this opportunity, understanding both the initial investment and ongoing operational costs – particularly electricity consumption – is crucial for calculating ROI. This guide from Yuhheng Technology Co., Ltd. provides detailed cost information and practical strategies to minimize energy usage.

BB Fertilizer Production Line Investment Costs

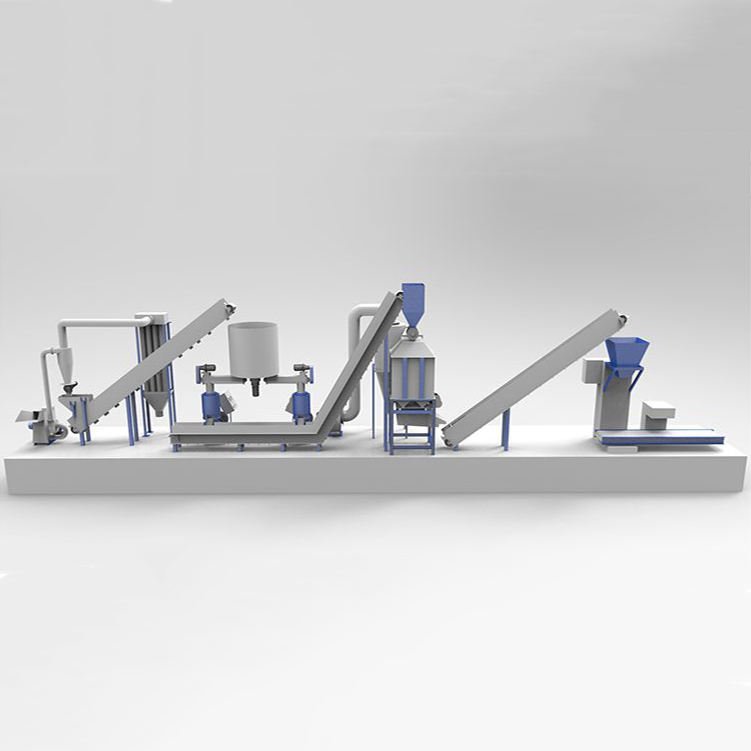

The cost of a BB fertilizer production line varies significantly based on capacity, automation level, and equipment configuration. Unlike complex granulation lines, BB systems are generally more affordable due to their simpler mechanical processes.

Production Line Investment Range:

- Basic Semi-Automatic Line: Suitable for small farms or startups, with capacity of 1-2 tons/hour. Includes manual batching, simple mixer, and basic packaging. Investment range: $18,000 – $40,000

- Standard Automatic Line: Ideal for commercial production, with capacity of 3-5 tons/hour. Features automatic batching systems, precision mixers, conveyor systems, and automated packaging. Investment range: $45,000 – $90,000

- Large-Scale Automated Plant: For high-volume production of 8-15+ tons/hour, with full PLC automation, robotic packaging, and sophisticated quality control systems. Investment range: $100,000 – $250,000+

Key Cost Factors:

- Degree of automation and control systems

- Mixer type and capacity (paddle mixers vs. ribbon mixers)

- Material handling system complexity

- Packaging automation level

- Equipment construction materials

Effective Strategies to Reduce Electricity Consumption

BB fertilizer production typically consumes less energy than granulation processes, but optimizing power usage remains essential for maximizing profitability. Here are proven strategies to reduce electricity costs:

1. Optimize Batching System Efficiency

- Install variable frequency drives (VFDs) on all conveyor motors

- Use gravity-fed systems where possible to reduce conveyor operation time

- Implement smart sequencing to minimize equipment idle time

- Group production batches by similar formulas to reduce cleaning frequency

2. Upgrade Mixing Equipment Efficiency

- Choose energy-efficient mixer designs (dual shaft paddle mixers typically use 30-40% less power than traditional designs)

- Install soft starters to reduce motor startup current

- Maintain optimal mixer loading levels (avoid under-loading or over-loading)

- Regularly inspect and maintain mixer seals and bearings to reduce friction

3. Implement Smart Automation Controls

- Use PLC systems to optimize equipment operation sequencing

- Install motion sensors to automatically stop conveyors when not in use

- Implement power management systems to avoid peak demand charges

- Use energy monitoring systems to identify high-consumption equipment

4. Optimize Material Handling

- Minimize conveyor lengths and elevation changes

- Use low-friction lining in conveyors and hoppers

- Install efficient bucket elevators with optimized belt tension

- Regular maintenance of all moving parts to reduce energy loss

5. Efficient Lighting and Facility Design

- Replace traditional lighting with LED fixtures

- Utilize natural lighting in production areas

- Install motion-activated lighting in storage areas

- Optimize plant layout to minimize material movement distances

6. Preventive Maintenance Program

- Regular lubrication of all bearings and moving parts

- Timely replacement of worn motor belts and chains

- Maintenance of electrical connections to prevent energy loss

- Cleaning of ventilation systems to reduce fan power requirements

7. Production Scheduling Optimization

- Schedule continuous production runs to avoid frequent startups

- Plan production during off-peak electricity hours when rates are lower

- Implement batch sequencing to minimize equipment cleaning between runs

- Use thermal imaging to identify energy loss points in electrical systems

Yuhheng Technology’s Energy-Efficient Solutions

At Yuhheng Technology Co., Ltd., we design BB fertilizer production lines with energy efficiency as a core consideration. Our solutions include:

Energy-Saving Features:

- High-efficiency motors with IE3/IE4 ratings

- Advanced PLC control systems for optimal power management

- Customized equipment design for specific material characteristics

- Integrated energy recovery systems

- Smart power monitoring and optimization software

Our Comprehensive Service:

- Energy consumption analysis and optimization planning

- Customized production line design for maximum efficiency

- Professional installation and commissioning services

- Operator training on energy-efficient operations

- Ongoing maintenance and optimization support

The energy-saving strategies outlined above can typically reduce electricity costs by 20-35%, with many optimization measures paying for themselves within 6-18 months through reduced operational expenses.

Contact Yuhheng Technology today for a detailed energy efficiency assessment and customized quotation. Our experts will help you design a BB fertilizer production line that minimizes energy costs while maintaining high production efficiency and product quality. Let us help you build a competitive and sustainable fertilizer blending business.

Leave a Comment

Your email address will not be published. Required fields are marked *