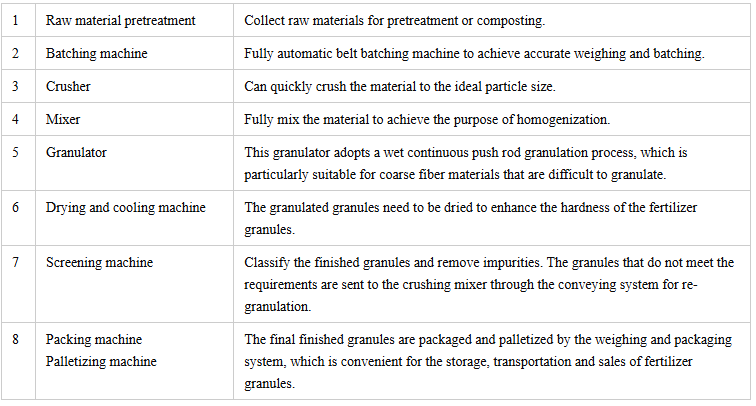

Description

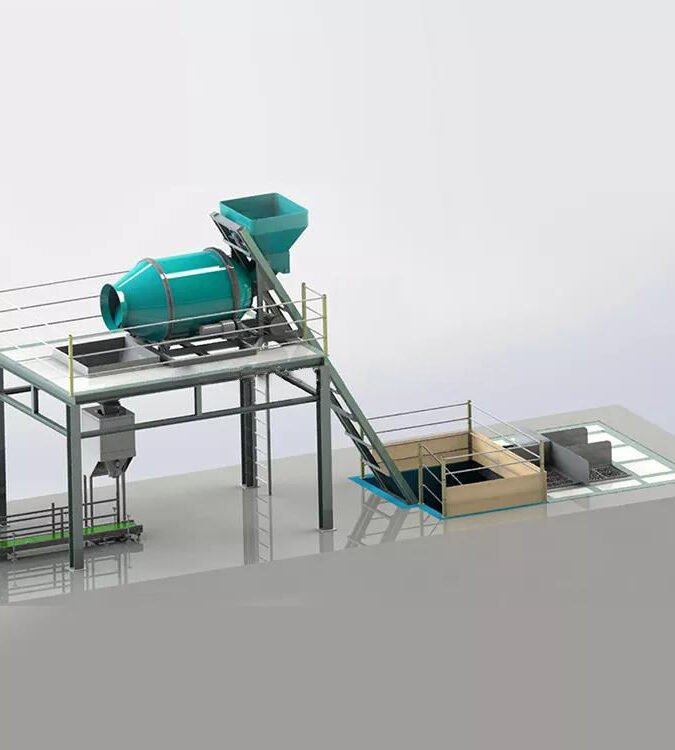

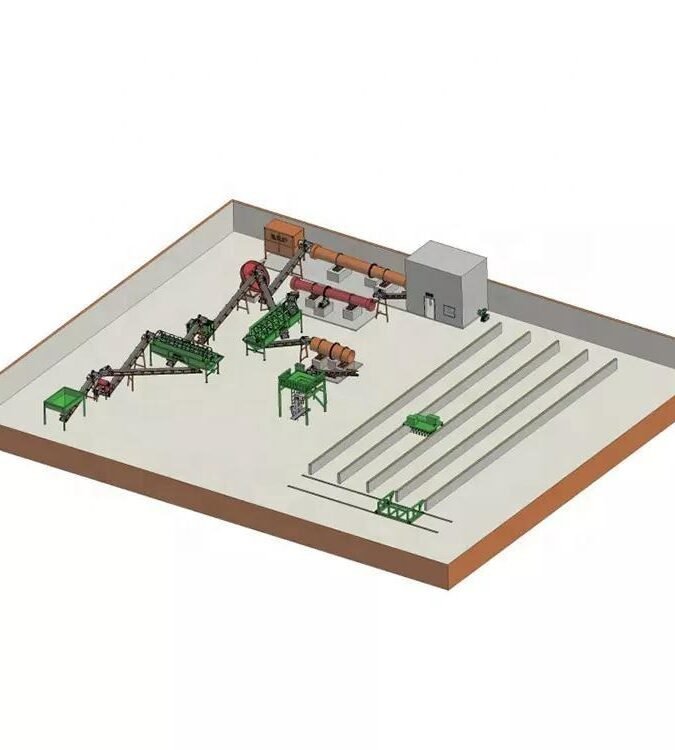

Organic Fertilizer Production Line

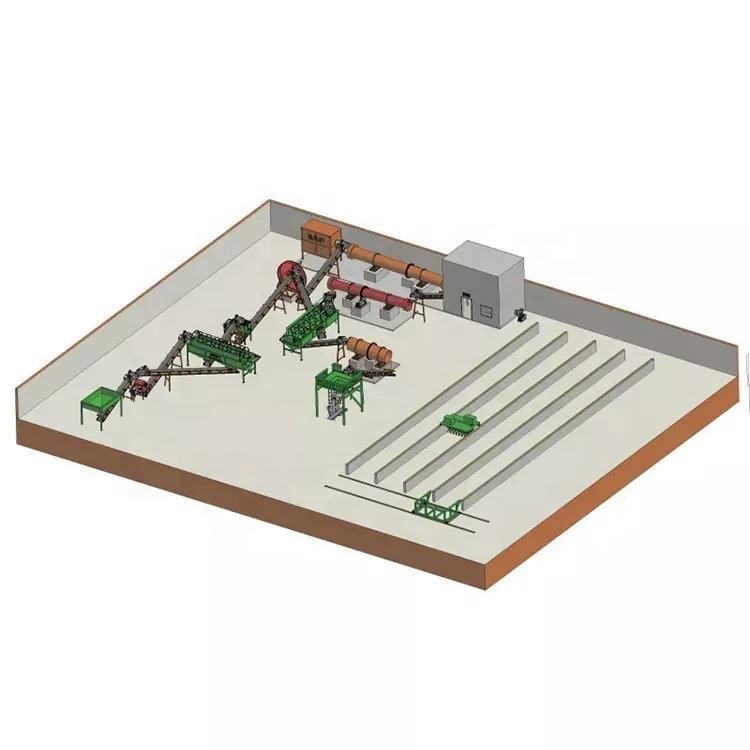

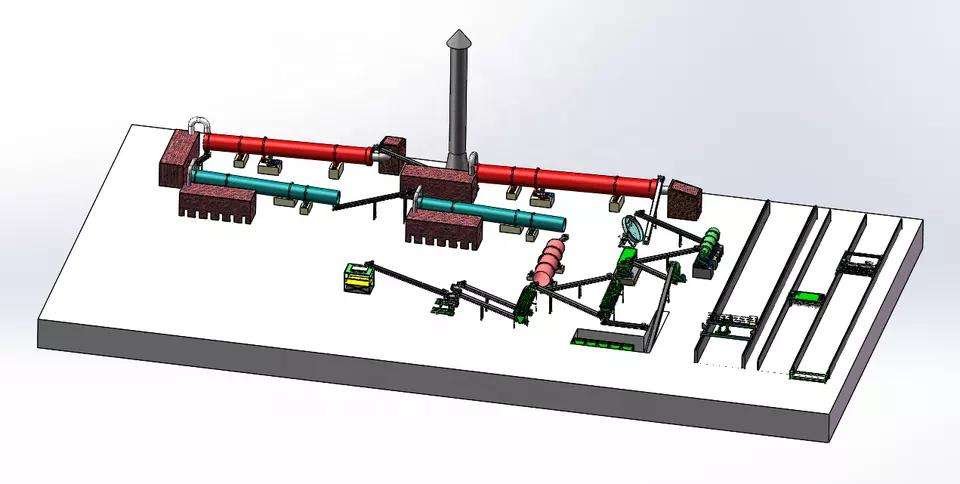

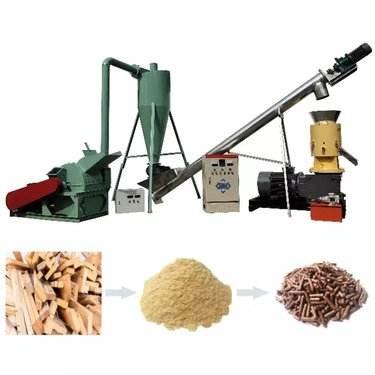

The organic fertilizer granulation production line is a set of comprehensive automated fertilizer production equipment designed for the production of granular fertilizers. It can convert organic waste or chemical raw materials into organic fertilizer granular products through a series of processes such as fermentation, crushing, mixing, granulation, drying, screening, packaging, etc. This production line is widely used in agriculture, gardening, environmental protection and other related fields.

Raw Materials of Organic Fertilizer Production Line

Agricultural waste: such as livestock and poultry manure, livestock and poultry breeding waste, straw, straw, etc. Crop residues: such as corn stalks, rice straw, bean stalks, etc. By-products in the agricultural production process: such as oil residue, bean dregs, etc. Food processing waste: such as fruit peels, pulp, food factory waste, etc. Urban domestic waste: such as kitchen waste, plant waste, etc. Sludge and sewage treatment residues: such as organic matter after sludge and sewage treatment. When processing these organic wastes, the organic fertilizer production line processes them through fermentation, composting and other processes, and finally produces high-quality organic fertilizers, which are used in agricultural production to improve soil fertility and improve soil structure

Working principle

The process of organic fertilizer production line is as follows:

1.Raw material fermentation— 2 Automatic belt scale batching system — 3 Crushing, mixing — 4 Disc granulation, drum granulation, extrusion granulation — 5 Dryer, Drying Organic Fertilizer Granules—6 Cooling Machine, Cooling Organic Fertilizer Particles— 7 Screening Machine. Screening Out Qualified Organic Fertilizer Particles — 8 Coating Membrane machine, coated film granules, making the granules smoother—-9 Packing scale, automatic filling organic fertilizer granules –10 seal

There are no reviews yet.