Organic Fertilizer Chain Plate Turning Machine Pig Manure Fermentation Equipment

原价为:$17,500.00。$13,600.00当前价格为:$13,600.00。

Description

Chain Plate Compost Turner

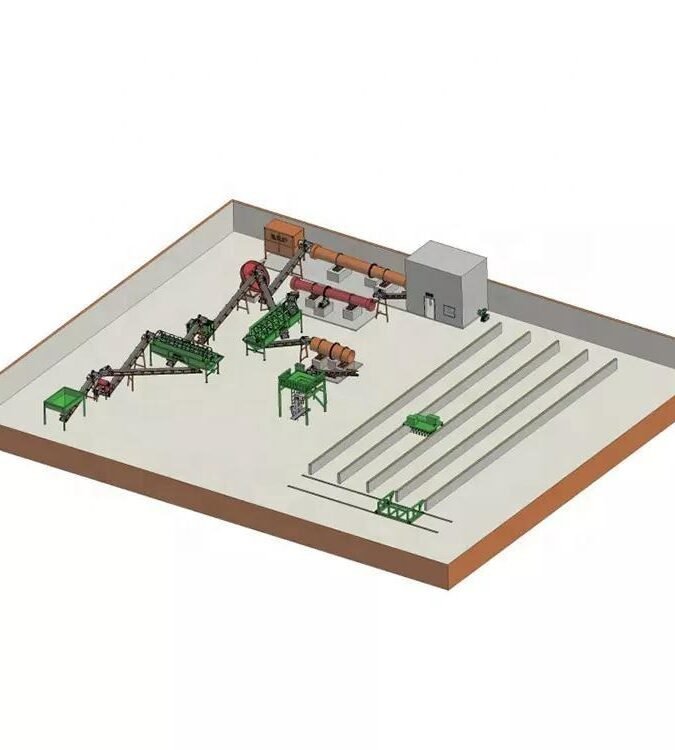

The chain plate compost turner is suitable for trough aerobic composting of organic solid waste such as livestock and poultry manure, sludge garbage, straw, etc. The walking system of the machine adopts variable frequency speed regulation, has good adaptability to different materials, runs smoothly, has high compost turning efficiency, and can perform deep trough operations.

It effectively shortens the fermentation cycle and improves production efficiency and product quality. The variable frequency speed regulation walking system can adapt well to changes in workload. The walking speed can be flexibly adjusted according to the material resistance, making the equipment more adaptable and flexible. The optional transfer vehicle can realize the sharing of multiple trough equipment. Under the condition that the equipment capacity allows, the production scale can be expanded by simply adding a fermentation tank, which improves the use value of the equipment.

Performance Characteristics:

* The bracket structure with chain drive and rolling support is adopted, which has small turning resistance and saves electricity and energy, and is suitable for deep groove operation.

* Flexible tension and elastic shock absorber are equipped with flip-flop bracket to protect transmission system and working parts.

* The turning pallet is equipped with a removable wear-resistant curved tooth blade, which has strong crushing ability and good stack oxygen filling effect.

* When flipping, the material stays on the tray for a long time, disperses at a high level, contacts with the air sufficiently, and is easy to precipitate.

* Through horizontal and vertical displacement, it is possible to realize the turnover operation at any position in the tank.

* The lifting and working parts are controlled by hydraulic system, flexible and safe.

* Remote control of the machine’s advance, lateral movement, flip and quick astern can be done remotely to improve the operating environment.

* Trough-type material distributor, automatic discharging device, solar fermentation chamber and ventilation and aeration system can be selected.

* Equipped with transfer machine to change groove, it can realize multi slot operation of a turn over machine and save investment.

Chain Plate Compost Turning Process:

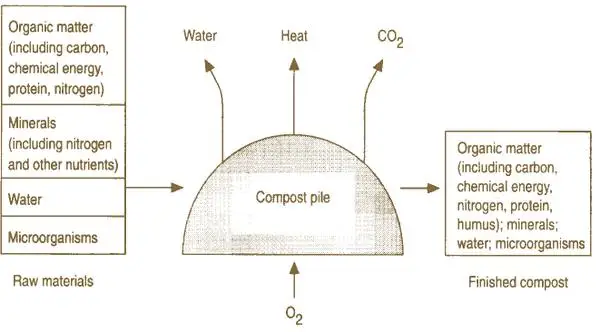

The first stage–grinding and piling:

Grinding: In “parameters affecting composting process”, we have analyzed the great importance of reducing the size particle of raw materials: lowering size of pellet materials will increase the surface area and promote micro-organism activity and accelerate the composting speed. Thereby, vertical grinder should be used to crush compostable raw materials before piling.

Piling: Compostable raw materials, such as sludge, municipal organic waste, poultry litter, chicken manure, swine manure, cow dung etc. are loaded into bunkers separated by concrete walls (left). Composting is done in bunkers with our chain plate compost turner system. The amounts of bunkers to be built depend on the quantities of raw materials to be decomposted.

The second stage–composting:

The mass bed is turned a minimum of every 7 days with a elevating belt compost turner which performs the turning function from the top of the piles. Elevating belt compost turner employs a backward-sloping conveyor with powerful teeth attached to the face of the inclined conveyor to lift the organic wastes up and over itself. The plates or teeth on the turning mechanism can be changed to provide more or less shredding action.

Working process: as the turner moves forward, the conveyor lifts the organic up the face and drop them off the back into the windrow, which allows for good size reduction, aeration and mixing. Its role is to turn the material from the existing windrow through and drop them back the turner machine to construct a new windrow as the material falls in the same bunker. It breaks the pile up with each turn.

In fertilizer production, some auxiliary materials must be added to adjust the carbon-nitrogen ratio, pH and water content of raw materials. The main raw materials and accessories that are roughly stacked together, the purpose of uniform mixing of different materials can be achieved while turning.

2. Conciliate the temperature of the raw material pile

A large amount of fresh air can be brought and fully contacted with the raw materials in the mixing pile, which can help aerobic microorganisms to actively generate fermentation heat and increase the pile temperature, and the heap temperature can cool down by the constant replenishment of fresh air. So that form a state of alternation of medium-temperature-temperature-temperature, and various beneficial microbial bacteria grow and reproduce rapidly in the temperature period.

3. Improve the permeability of raw material piles

The groove type composting turner can process the material into smaller pieces, making the material pile thick and compact, fluffy and elastic, forming a suitable porosity between the materials.

4. Adjust the moisture of the raw material pile

The suitable moisture content of raw material fermentation is about 55%. In the fermentation of the turning operation, the active biochemical reactions of aerobic microorganisms will generate new moisture, and the consumption of raw materials by oxygen-consuming microorganisms will also cause the water to lose the carrier and free out. Therefore, with the fertilization process, water will be reduced in time. In addition to the evaporation formed by heat conduction, the turning raw materials will form compulsory water vapor emission.

- Sprinkle the fertilizer base materials such as the piled livestock and poultry manure and other materials, domestic garbage, sludge, etc. with biological fermentation inoculants.

- Use a turning machine to evenly mix the straw, livestock and poultry manure and other organic materials, domestic garbage, sludge, (water content should be 50%-60%), fermentation bacteria agent, etc., and it can be deodorized in 3-5 hours. , 16 hours to heat up to 50 degrees (about 122 degrees Fahrenheit), when the temperature reaches 55 degrees (about 131 degrees Fahrenheit), turn the heap again to add oxygen, and then start stirring whenever the temperature of the material reaches 55 degrees to achieve uniform fermentation, The effect of increasing oxygen and cooling, and then repeat this process until it is completely decomposed.

5. The general fertilization process takes 7-10 days. Due to different climates in different places, it may take 10-15 days for the material to be completely decomposed. high, potassium content increased. Powdered organic fertilizer is made.

There are no reviews yet.